Lap Joint Flanges

supplying All Over World

About Lap Joint Flanges

Jubilant Piping Solution PVT. LTD offers Lap joint pipe flanges in all available material, size and dimensions. Lap Joint flanges slide over the pipe and are utilized with stub end fittings. It is allowed to turn around the stub end and it ensures you that there will not be any issues with bolt hole alignment. It is used in the applications that need frequent dismantling.

ANSI/ASME B16.5 Lap Joint Flanges with the stub end used in piping systems where bolting pressure is transmitted to the gasket by the pressure of the flange against the back of the pipe. These includes in various materials such as stainless steel, carbon steel, alloy steel, monel and nickel available in number of classes like 150LB, 300LB, 400LB, 600LB, 900LB, 1500LB according to the customer specification.

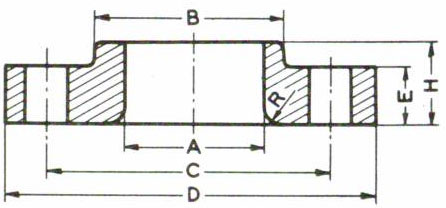

Dimensions of ANSI B16.5 Lap Joint Flanges

| Nominal Bore Lap Joint Flanges | Dia.(D) | Thick.(E) | Dia.(B) | Dia.(A) | Height(H) | Nbr | Holes | Dia.(C) |

|---|---|---|---|---|---|---|---|---|

|

1/2″

|

90

|

11.2

|

30

|

22.9

|

16

|

4

|

15.87

|

60.3

|

|

3/4″

|

100

|

12.7

|

38

|

28.2

|

16

|

4

|

15.87

|

69.9

|

|

1″

|

110

|

14.3

|

49

|

34.9

|

17

|

4

|

15.87

|

79.4

|

|

1 1/4″

|

115

|

15.9

|

59

|

43.7

|

21

|

4

|

15.87

|

88.9

|

|

1 1/2″

|

125

|

17.5

|

65

|

50.0

|

22

|

4

|

15.87

|

98.4

|

|

2″

|

150

|

20.7

|

78

|

62.5

|

25

|

4

|

19.05

|

120.7

|

|

2 1/2″

|

180

|

22.3

|

90

|

75.4

|

29

|

4

|

19.05

|

139.7

|

|

3″

|

190

|

23.9

|

108

|

91.4

|

30

|

4

|

19.05

|

152.4

|

|

3 1/2″

|

215

|

23.9

|

122

|

104.1

|

32

|

8

|

19.05

|

177.8

|

|

4″

|

230

|

23.9

|

135

|

116.8

|

33

|

8

|

19.05

|

190.5

|

|

5″

|

255

|

23.9

|

164

|

144.4

|

36

|

8

|

22.22

|

215.9

|

|

6″

|

280

|

25.4

|

192

|

171.4

|

40

|

8

|

22.22

|

241.3

|

|

8″

|

345

|

28.6

|

246

|

222.2

|

44

|

8

|

22.22

|

298.5

|

|

10″

|

405

|

30.2

|

305

|

277.4

|

49

|

12

|

25.40

|

362.0

|

|

12″

|

485

|

31.8

|

365

|

328.2

|

56

|

12

|

25.40

|

431.8

|

|

14″

|

535

|

35.0

|

400

|

360.2

|

79

|

12

|

28.57

|

476.3

|

|

16″

|

595

|

36.6

|

457

|

411.2

|

87

|

16

|

28.57

|

539.8

|

|

18″

|

635

|

39.7

|

505

|

462.3

|

97

|

16

|

31.75

|

577.9

|

|

20″

|

700

|

42.9

|

559

|

514.4

|

103

|

20

|

31.75

|

635.0

|

|

24″

|

815

|

47.7

|

663

|

616.0

|

111

|

20

|

34.92

|

749.3

|

Lap Joint Flanges Material Grades

| Material | Grades |

|---|---|

| Stainless Steel | ASTM A182 F Gr.304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Carbon Steel | ASTM / ASME A/SA 105, ASTM A181 LF2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 |

| LTCS | ASTM A350 / ASME SA350, LF2, LF3 |

| Alloy Steel | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel | ASTM A182, ASME SA 182 UNS S31803, UNS S32205 (Dual Certified). |

| Super Duplex Steel | ASTM A182, ASME SA 182, UNS S32750, UNS S32760, UNS S32790 |

| High Nickel Alloy | ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |

Industries We Serve