Blind Flanges

supplying All Over World

About Blind Flanges

Blind Flanges are used for testing the flow of gas or liquid through a pipeline or vessel. It helps to close the end of piping systems or vessel openings. It allows easy access to the pipeline when there is a requirement to work done inside the line. They are used in high pressure applications available in all grades, materials, size and specifications. Blind pipe flanges are typically provided with a raised face, flat face, or RTJ facing.

The standard height is 1/16" when a raised face is required under 400#. The standard height is 1/4".for blind pipe flanges of 400# and above. Jubilant Piping Solution PVT. LTD manufactures blind flanges in various materials such as stainless steel, carbon steel, alloy steel and monel according to the various standard ANSI/ASME/ASTM according to the customer requirement.

150 lb Blind flange dimensions

| Nominal Pipe Size |

"A" (O.D.) |

"B" (Thk.) |

"C" (RF Dia.) |

"D" (B.C.D.) |

# Bolt Holes |

Dia. of Bolt Holes |

Approx. Weight |

|---|---|---|---|---|---|---|---|

| 1/2" | 3-1/2 | 7/16 | 1-3/8 | 2-3/8 | 4 | 5/8 | 2 |

| 3/4" | 3-7/8 | 1/2 | 1-11/16 | 2-3/4 | 4 | 5/8 | 2 |

| 1" | 4-1/4 | 9/16 | 2 | 3-1/8 | 4 | 5/8 | 2 |

| 1-1/4" | 4-5/8 | 5/8 | 2-1/2 | 3-1/2 | 4 | 5/8 | 3 |

| 1-1/2" | 5 | 11/16 | 2-7/8 | 3-7/8 | 4 | 5/8 | 3 |

| 2" | 6 | 3/4 | 3-5/8 | 4-3/4 | 4 | 3/4 | 4 |

| 2-1/2" | 7 | 7/8 | 4-1/8 | 5-1/2 | 4 | 3/4 | 7 |

| 3" | 7-1/2 | 15/16 | 5 | 6 | 4 | 3/4 | 9 |

| 3-1/2" | 8-1/2 | 15/16 | 5-1/2 | 7 | 8 | 3/4 | 13 |

| 4" | 9 | 15/16 | 6-3/16 | 7-1/2 | 8 | 3/4 | 17 |

| 5" | 10 | 15/16 | 7-5/16 | 8-1/2 | 8 | 7/8 | 20 |

| 6" | 11 | 1 | 8-1/2 | 9-1/2 | 8 | 7/8 | 27 |

| 8" | 13-1/2 | 1-1/8 | 10-5/8 | 11-3/4 | 8 | 7/8 | 47 |

| 10" | 16 | 1-3/16 | 12-3/4 | 14-1/4 | 12 | 1 | 67 |

| 12" | 19 | 1-1/4 | 15 | 17 | 12 | 1 | 123 |

| 14" | 21 | 1-3/8 | 16-1/4 | 18-3/4 | 12 | 1-1/8 | 139 |

| 16" | 23-1/2 | 1-7/16 | 18-1/2 | 21-1/4 | 16 | 1-1/8 | 187 |

| 18" | 25 | 1-9/16 | 21 | 22-3/4 | 16 | 1-1/4 | 217 |

| 20" | 27-1/2 | 1-11/16 | 23 | 25 | 20 | 1-1/4 | 283 |

| 24" | 32 | 1-7/8 | 27-1/4 | 29-1/2 | 20 | 1-3/8 | 415 |

| 1/16" raised face included in flange thickness. | |||||||

Class 300 Blind Flange Dimensions

| Nominal Pipe Size |

"A" (O.D.) |

"B" (Thk.) |

"C" (RF Dia.) |

"D" (B.C.D.) |

# Bolt Holes |

Dia. of Bolt Holes |

Approx. Weight |

|---|---|---|---|---|---|---|---|

| 1/2" | 3-3/4 | 9/16 | 1-3/8 | 2-5/8 | 4 | 5/8 | 2 |

| 3/4" | 4-5/8 | 5/8 | 1-11/16 | 3-1/4 | 4 | 3/4 | 3 |

| 1" | 4-7/8 | 11/16 | 2 | 3-1/2 | 4 | 3/4 | 4 |

| 1-1/4" | 5-1/4 | 3/4 | 2-1/2 | 3-7/8 | 4 | 3/4 | 6 |

| 1-1/2" | 6-1/8 | 13/16 | 2-7/8 | 4-1/2 | 4 | 7/8 | 7 |

| 2" | 6-1/2 | 7/8 | 3-5/8 | 5 | 8 | 3/4 | 8 |

| 2-1/2" | 7-1/2 | 1 | 4-1/8 | 5-7/8 | 8 | 7/8 | 12 |

| 3" | 8-1/4 | 1-1/8 | 5 | 6-5/8 | 8 | 7/8 | 16 |

| 3-1/2" | 9 | 1-3/16 | 5-1/2 | 7-1/4 | 8 | 7/8 | 21 |

| 4" | 10 | 1-1/4 | 6-3/16 | 7-7/8 | 8 | 7/8 | 28 |

| 5" | 11 | 1-3/8 | 7-5/16 | 9-1/4 | 8 | 7/8 | 37 |

| 6" | 12-1/2 | 1-7/16 | 8-1/2 | 10-5/8 | 12 | 7/8 | 48 |

| 8" | 15 | 1-5/8 | 10-5/8 | 13 | 12 | 1 | 79 |

| 10" | 17-1/2 | 1-7/8 | 12-3/4 | 15-1/4 | 16 | 1-1/8 | 122 |

| 12" | 20-1/2 | 2 | 15 | 17-3/4 | 16 | 1-1/4 | 183 |

| 14" | 23 | 2-1/8 | 16-1/4 | 20-1/4 | 20 | 1-1/4 | 241 |

| 16" | 25-1/2 | 2-1/4 | 18-1/2 | 22-1/2 | 20 | 1-3/8 | 315 |

| 18" | 28 | 2-3/8 | 21 | 24-3/4 | 24 | 1-3/8 | 414 |

| 20" | 30-1/2 | 2-1/2 | 23 | 27 | 24 | 1-3/8 | 515 |

| 24" | 36 | 2-3/4 | 27-1/4 | 32 | 24 | 1-5/8 | 800 |

| 1/16" raised face included in flange thickness. | |||||||

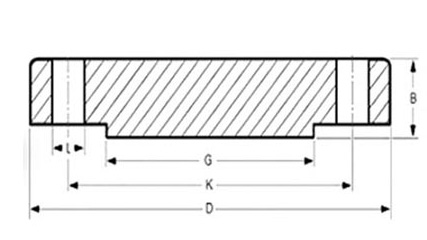

Class 600 Blind Flange Dimensions

| ANSI/ASME/ASA B16.5 600lb/sq.in. Flange BLIND-RF | |||||||

|---|---|---|---|---|---|---|---|

| ø | D | b | g | k | Holes | l | Kg. |

| 1/2" | 95,2 | 14,3 | 34,9 | 66,7 | 4 | 15,9 | 0,700 |

| 3/4" | 117,5 | 15,9 | 42,9 | 82,5 | 4 | 19,0 | 1,200 |

| 1" | 123,8 | 17,5 | 50,8 | 88,9 | 4 | 19,0 | 1,500 |

| 1 1/4" | 133,3 | 20,6 | 63,5 | 98,4 | 4 | 19,0 | 2,000 |

| 1 1/2" | 155,6 | 22,2 | 73,0 | 114,3 | 4 | 22,2 | 3,200 |

| 2" | 165,1 | 25,4 | 92,1 | 127,0 | 8 | 19,0 | 4,300 |

| 2 1/2" | 190,5 | 28,6 | 104,8 | 149,2 | 8 | 22,2 | 6,000 |

| 3" | 209,5 | 31,7 | 127,0 | 168,3 | 8 | 22,2 | 8,000 |

| 3 1/2" | 228,6 | 34,9 | 139,7 | 184,1 | 8 | 25,4 | 10,500 |

| 4" | 273,0 | 38,1 | 157,2 | 215,9 | 8 | 25,4 | 18,000 |

| 5" | 330,2 | 44,4 | 185,7 | 266,7 | 8 | 28,6 | 28,500 |

| 6" | 355,6 | 47,6 | 215,9 | 292,1 | 12 | 28,6 | 35,500 |

| 8" | 419,1 | 55,6 | 269,9 | 349,2 | 12 | 31,7 | 58,000 |

| 10" | 508,0 | 63,5 | 323,8 | 431,8 | 16 | 34,9 | 98,000 |

| 12" | 558,8 | 66,7 | 381,0 | 488,9 | 20 | 34,9 | 125,000 |

| 14" | 603,2 | 69,8 | 412,7 | 527,0 | 20 | 38,1 | 151,000 |

| 16" | 685,8 | 76,2 | 469,9 | 603,2 | 20 | 41,3 | 215,000 |

| 18" | 742,9 | 82,5 | 533,4 | 654,0 | 20 | 44,4 | 287,000 |

| 20" | 812,8 | 88,9 | 584,2 | 723,9 | 24 | 44,4 | 366,000 |

| 22" | 869,9 | 95,2 | 641,2 | 777,9 | 24 | 47,6 | 437,000 |

| 24" | 939,8 | 101,6 | 692,1 | 838,2 | 24 | 50,8 | 532,000 |

Blind Flanges Material Grades

| Material | Grades |

|---|---|

| Stainless Steel | ASTM A182 F Gr.304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Carbon Steel | ASTM / ASME A/SA 105, ASTM A181 LF2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 |

| LTCS | ASTM A350 / ASME SA350, LF2, LF3 |

| Alloy Steel | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel | ASTM A182, ASME SA 182 UNS S31803, UNS S32205 (Dual Certified). |

| Super Duplex Steel | ASTM A182, ASME SA 182, UNS S32750, UNS S32760, UNS S32790 |

| High Nickel Alloy | ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |

Industries We Serve