Reducing Flanges

supplying All Over World

About Reducing Flanges

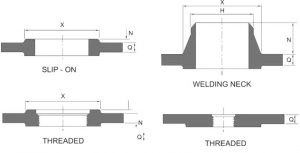

Reducing Flange is a device particularly designed to make two pipes fit together. A Reducing Flange is used when there is a change in the diameter of both the pipes. There are different types of reducer flanges such as slip-on, blind, weld-neck and threaded flanges. These Reducing Flange are present in all types of pressure classes ( i.e. – ANSI classes 150, 300, 400, 600, 900, 1500 & 2500 and DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160 ).

One of the benefits of using the Reducing Flange is that they are both durable as well as corrosion resistant in nature. Apart from playing a crucial role in connecting larger pipes to smaller ones, most suppliers prefer the using the Reducing Flange Class 600 because they are a highly economical way to make transitions between two pipes of very different sizes. All the fore mentioned reasons make the Reducing Flange Awwa C207 Class D very cost – efficient.

Dimensions of ANSI B16.5 Reducing flanges

| NPS (Inches) |

DN (mm) |

FLANGE OD A MM |

FLANGE THICKNESS D MM |

SLIP ON FLANGE WEIGHT (KGS) | WELD NECK FLANGE WEIGHT (KGS) | BLIND FLANGE WEIGHT (KGS) |

| 1/ 2 | 15 | 88.9 | 11.2 | 0.4 | 0.5 | 0.4 |

| 3/ 4 | 20 | 98.6 | 12.7 | 0.6 | 0.7 | 0.6 |

| 1 | 25 | 108 | 14.2 | 0.8 | 1 | 0.9 |

| 1 1/ 4 | 32 | 117.3 | 15.7 | 1 | 1.3 | 1.2 |

| 1 1/ 2 | 40 | 127 | 17.5 | 1.3 | 1.7 | 1.5 |

| 2 | 50 | 152.4 | 19.1 | 2.1 | 2.6 | 2.4 |

| 2 1/ 2 | 65 | 177.8 | 22.4 | 3.3 | 4.1 | 3.9 |

| 3 | 80 | 190.5 | 23.9 | 3.9 | 4.9 | 4.9 |

| 3 1/ 2 | 90 | 215.9 | 23.9 | 4.8 | 6.1 | 6.2 |

| 4 | 100 | 228.6 | 23.9 | 5.3 | 6.8 | 7.0 |

| 5 | 125 | 254 | 23.9 | 6.1 | 8.6 | 8.6 |

| 6 | 150 | 279.4 | 25.4 | 7.5 | 10.6 | 11.3 |

| 8 | 200 | 342.9 | 28.4 | 12.1 | 17.6 | 19.6 |

| 10 | 250 | 406.4 | 30.2 | 16.5 | 24 | 28.6 |

| 12 | 300 | 482.6 | 31.8 | 26.2 | 36.5 | 43.2 |

| 14 | 350 | 533.4 | 35.1 | 34.6 | 48.4 | 58.1 |

| 16 | 400 | 596.9 | 36.6 | 44.8 | 60.6 | 76.1 |

| 18 | 450 | 635 | 39.6 | 48.9 | 68.3 | 93.7 |

| 20 | 500 | 698.5 | 42.9 | 61.9 | 84.5 | 122.0 |

| 24 | 600 | 812.8 | 47.8 | 86.9 | 115 | 185.0 |

Reducing Flanges Material Grades

| Material | Grades |

|---|---|

| Stainless Steel | ASTM A182 F Gr.304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Carbon Steel | ASTM / ASME A/SA 105, ASTM A181 LF2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 |

| LTCS | ASTM A350 / ASME SA350, LF2, LF3 |

| Alloy Steel | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel | ASTM A182, ASME SA 182 UNS S31803, UNS S32205 (Dual Certified). |

| Super Duplex Steel | ASTM A182, ASME SA 182, UNS S32750, UNS S32760, UNS S32790 |

| High Nickel Alloy | ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |

Industries We Serve