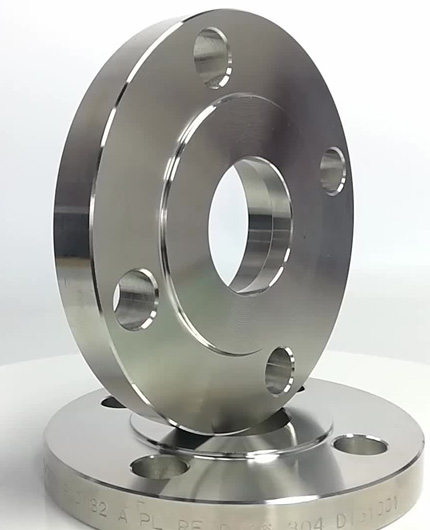

Socket weld Flanges

supplying All Over World

About Socket weld Flanges

Socket Weld Flange Din En 1092-1 Is Connected To A Pipe With The Help Of A Single Fillet Weld, That Is Executed On The Outer Side Of The Flange. Although The Socket Weld Flange Is Different From The Slip-On Flange Type, Which Requires Two Welds. According To ASME B31.1, The Execution Of SW Flange Connection Using A Socket Weld Flange, Is By First Inserting The Pipe In The Socket Of The Flange Until It Reaches The Bottom Of The Flange.

This gap shall be left by the Stainless Steel Socket Weld Flange Manufacturer In India to allow proper positioning of the pipe inside the flange socket. This is done after the solidification of the weld. Socket Weld Flange Awwa C207 Class D is generally used for small-size and high-pressure piping systems that do not transfer highly corrosive fluid media. This because these API 6A SWRF Flange types are a subject to corrosion in the presence of a gap between the end of the pipe and the shoulder of the socket.

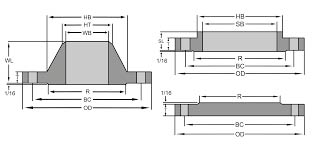

150 lb socket weld flange dimensions

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore Socket Weld | Dia.(D) | Thick.(E) | Dia.(F) | Dia.(B) | Dia.(A) | Height1(H) | Nbr | Holes | Dia.(C) |

|

1/2″

|

90

|

11.2

|

35.05

|

30

|

22.2

|

14

|

4

|

15.87

|

60.3

|

|

3/4″

|

100

|

12.7

|

42.92

|

38

|

27.7

|

14

|

4

|

15.87

|

69.9

|

|

1″

|

110

|

14.3

|

50.80

|

49

|

34.5

|

16

|

4

|

15.87

|

79.4

|

|

1 1/4″

|

115

|

15.9

|

63.50

|

59

|

43.2

|

19

|

4

|

15.87

|

88.9

|

|

1 1/2″

|

125

|

17.5

|

73.15

|

65

|

49.5

|

21

|

4

|

15.87

|

98.4

|

|

2″

|

150

|

19.1

|

91.94

|

78

|

61.9

|

24

|

4

|

19.05

|

120.7

|

|

2 1/2″

|

180

|

22.3

|

104.65

|

90

|

74.6

|

27

|

4

|

19.05

|

139.7

|

|

3″

|

190

|

23.9

|

127.00

|

108

|

90.7

|

29

|

4

|

19.05

|

152.4

|

300# socket weld flange dimensions

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore Socket Weld | Dia.(D) | Thick.(E) | Dia.(F) | Dia.(B) | Dia.(A) | Height1(H) | Nbr | Holes | Dia.(C) |

|

1/2″

|

95

|

12.7

|

35.05

|

38

|

22.2

|

21

|

4

|

15.87

|

66.7

|

|

3/4″

|

115

|

14.3

|

42.92

|

48

|

27.7

|

24

|

4

|

19.05

|

82.6

|

|

1″

|

125

|

15.9

|

50.80

|

54

|

34.5

|

25

|

4

|

19.05

|

88.9

|

|

1 1/4″

|

135

|

17.5

|

63.50

|

64

|

43.2

|

25

|

4

|

19.05

|

98.4

|

|

1 1/2″

|

155

|

19.1

|

73.15

|

70

|

49.5

|

29

|

4

|

22.22

|

114.3

|

|

2″

|

165

|

20.7

|

91.94

|

84

|

61.9

|

32

|

8

|

19.05

|

127.0

|

|

2 1/2″

|

190

|

23.9

|

104.65

|

100

|

74.6

|

37

|

8

|

22.22

|

149.2

|

|

3″

|

210

|

27.0

|

127.00

|

117

|

90.7

|

41

|

8

|

22.22

|

168

|

Socket weld Flanges Material Grades

| Material | Grades |

|---|---|

| Stainless Steel | ASTM A182 F Gr.304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Carbon Steel | ASTM / ASME A/SA 105, ASTM A181 LF2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 |

| LTCS | ASTM A350 / ASME SA350, LF2, LF3 |

| Alloy Steel | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel | ASTM A182, ASME SA 182 UNS S31803, UNS S32205 (Dual Certified). |

| Super Duplex Steel | ASTM A182, ASME SA 182, UNS S32750, UNS S32760, UNS S32790 |

| High Nickel Alloy | ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |

Industries We Serve